As the fundamental shifts embodied by Industry 4.0 continue to transform how goods are produced, new and innovative methods are being developed to further improve and streamline existing processes. One area that is seeing a great deal of modernization is quality control. By automating quality control processes, it is possible to ensure that raw materials meet the needs of the industries for which they are produced, and also to save time and money. These improvements can have the effect of increasing global supplies of materials, while simultaneously reducing the costs of those materials.

We recently built a system to analyze the production quality of steel sheet metal, and to detect defects using computer vision and machine learning. This was done using inexpensive hardware and the user-friendly Edge Impulse platform, proving that Industry 4.0 techniques are not only accessible to huge corporations, but also to small businesses.

Our method can run on a variety of hardware, ranging from a laptop to an NVIDIA Jetson, Raspberry Pi, or OpenMV Cam. Images of steel sheet metal are captured by such a device, then are fed into a neural network classifier. The network will then determine if a number of defects are present in the metal, including crescent gaps, inclusions, oil spots, punching holes, waist folding, water spots, and welding lines. This information can be used during the manufacturing process to either sort the steel by quality, or to discard defective sheets.

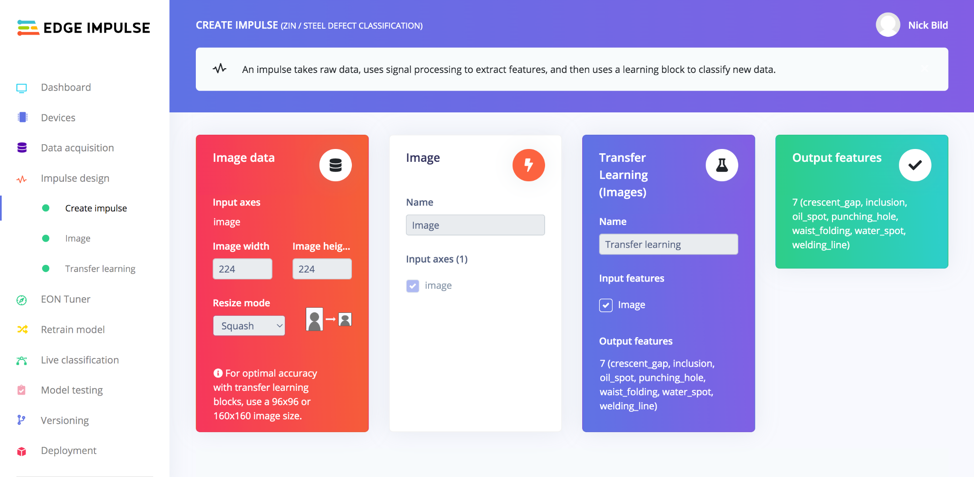

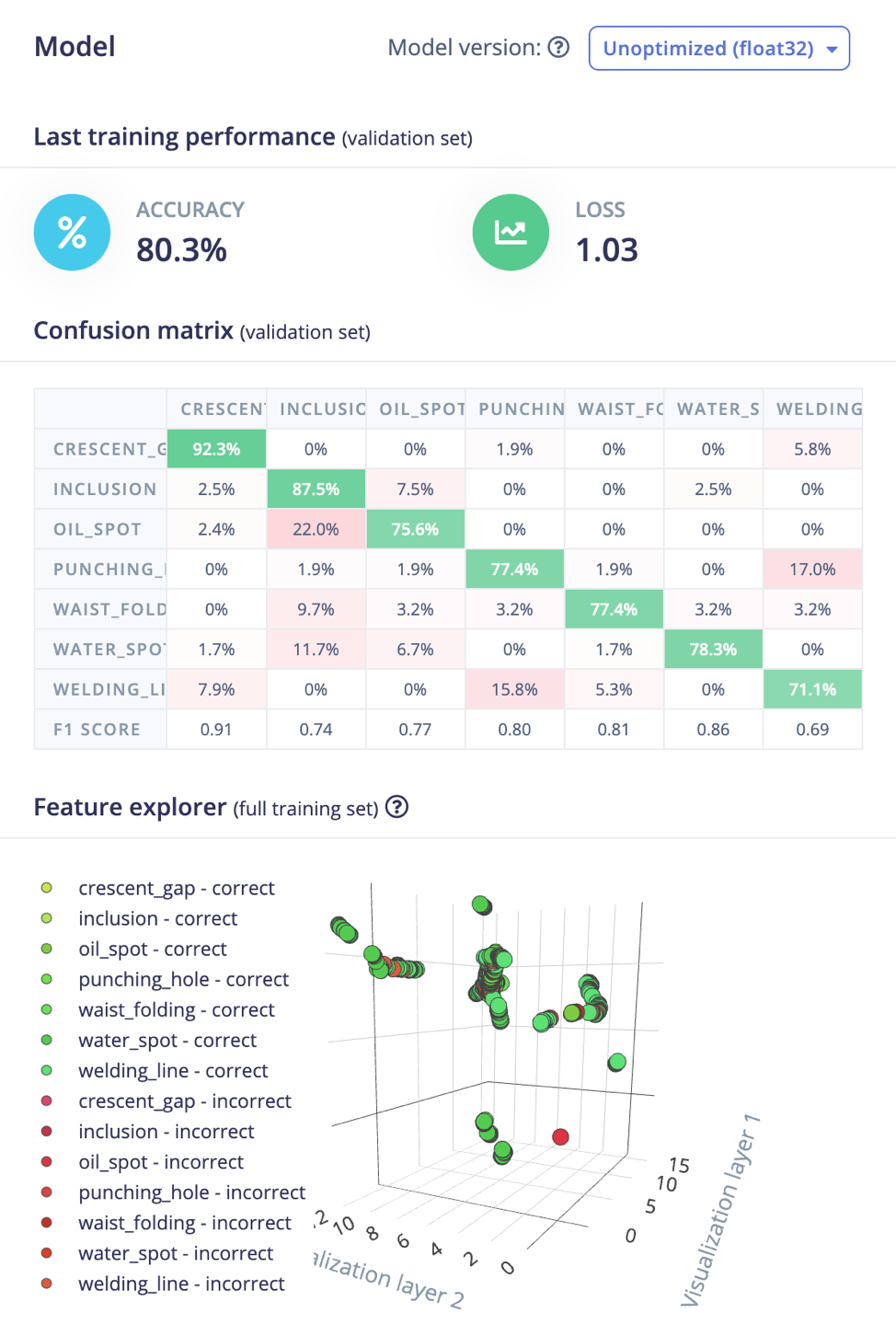

To make this system work, a training dataset was first located and uploaded to Edge Impulse. Next, the images were preprocessed to reduce the computational overhead associated with the classification task. Finally, transfer learning was utilized to take advantage of a MobileNetV2 model that had already been pretrained on a very large image database. This model was then further trained on the 1,573 image dataset previously collected to allow it to recognize defects in steel. Validation of the trained model showed that classification accuracy had reached 80.3%.

Deploying the model to hardware for real world use is a snap using tools built into Edge Impulse. A few button clicks will deliver the machine learning data analysis pipeline to any of the currently supported boards, or virtually any other hardwa re by exporting it as a C++ library.

We see our work as opening the door to enhanced industrial automation for companies of any size. By detecting production problems, and by catching problems in the field, we hope to improve safety in many application areas, while also reducing costs. Another benefit of identifying defects quickly is that it can serve as an early warning that certain manufacturing equipment may need servicing.

To better understand how Industry 4.0 can work for you, take a look at the public Edge Impulse project.

Want to see Edge Impulse in action? Schedule a demo today.