Back in December, we teamed up with SparkFun, Advantech, and NVIDIA to host a virtual workshop that focused on implementing artificial intelligence and machine learning in manufacturing using a Jetson Nano.

Automated smart factories are leveraging AI and ML to analyze data, run systems, and improve processes over time. In manufacturing, computer vision on the edge is an increasingly popular IoT application used in safety and quality assurance applications.

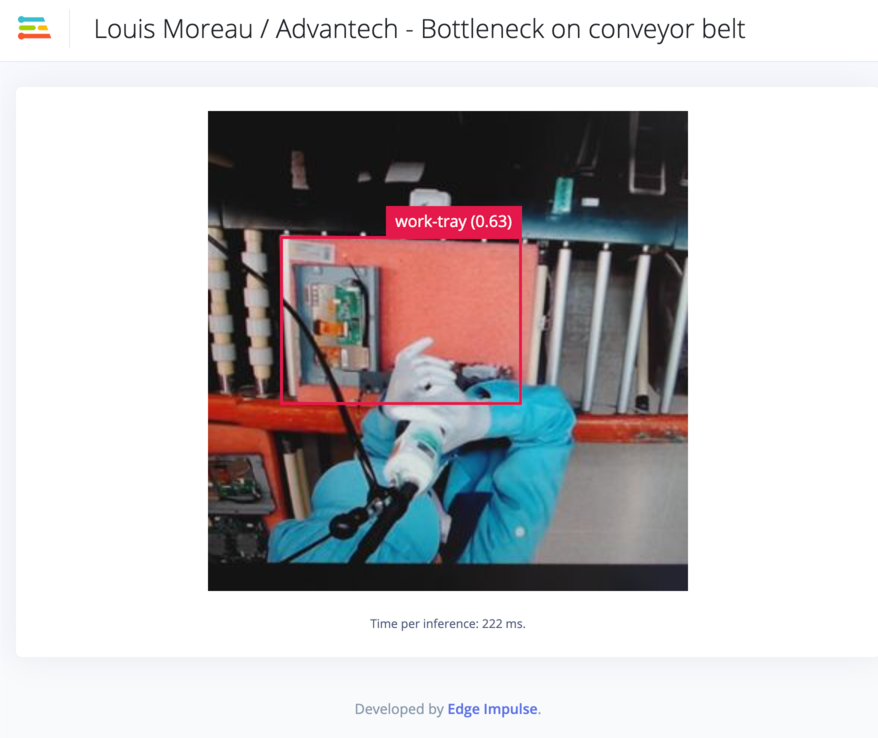

Led by Louis Moreau (Edge Impulse Senior DevRel Engineer) and Charlie Wu (Product Manager at Advantech), the session covered a range of topics including how to:

- Apply ML models on factory floor cameras and run calculations and return output for monitoring and troubleshooting of equipment and production environments - ensuring compliance and upholding worker safety.

- Use cached video streams for auditing model retraining, recognize defects and anomalies in your manufacturing environment.

- Detect personal protective equipment (PPE) and monitor building entrances for personnel security.

- Use smart notifications to enable people to intervene at certain steps in the automation, as part of the intelligence captured by the models, creating a continuous cycle of training, testing and validating processes.

- Learn how Edge Impulse MLOps can automate ML models for complex decision-making, enabling teams who build, train, evaluate, and deploy the models.

The workshop’s tutorial can also be found on GitHub.