Large manufacturing facilities, warehouses, and distribution centers have very complex yard processes that can be a logistical nightmare. Getting all the day’s trucks into the right places at the right times to be loaded or unloaded and sent on their way can be a very daunting task. The consequences of inefficient yard management range from financial losses and missed opportunities to customer dissatisfaction. The importance of yard management may sometimes take a backseat to larger scale supply chain considerations, like transportation and warehousing operations, but given how significantly poor yard management can impact the bottom line, every effort should be made to streamline these processes.

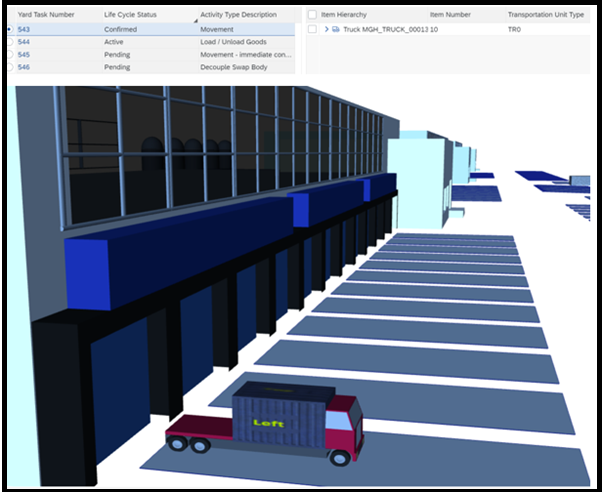

The team at SAP is no stranger to this problem, having designed an application, called Yard Logistics, that helps yard managers to streamline operations. Recognizing the growing importance of tinyML in industry, a group of engineers at SAP recently built a machine learning-powered tool to integrate with their existing logistics software suite that offers the promise of further improving the efficiency of yard operations. They found that by using computer vision and a machine learning classifier developed with Edge Impulse, it was possible to automate previously manual steps in the process that consistently slowed operations down.

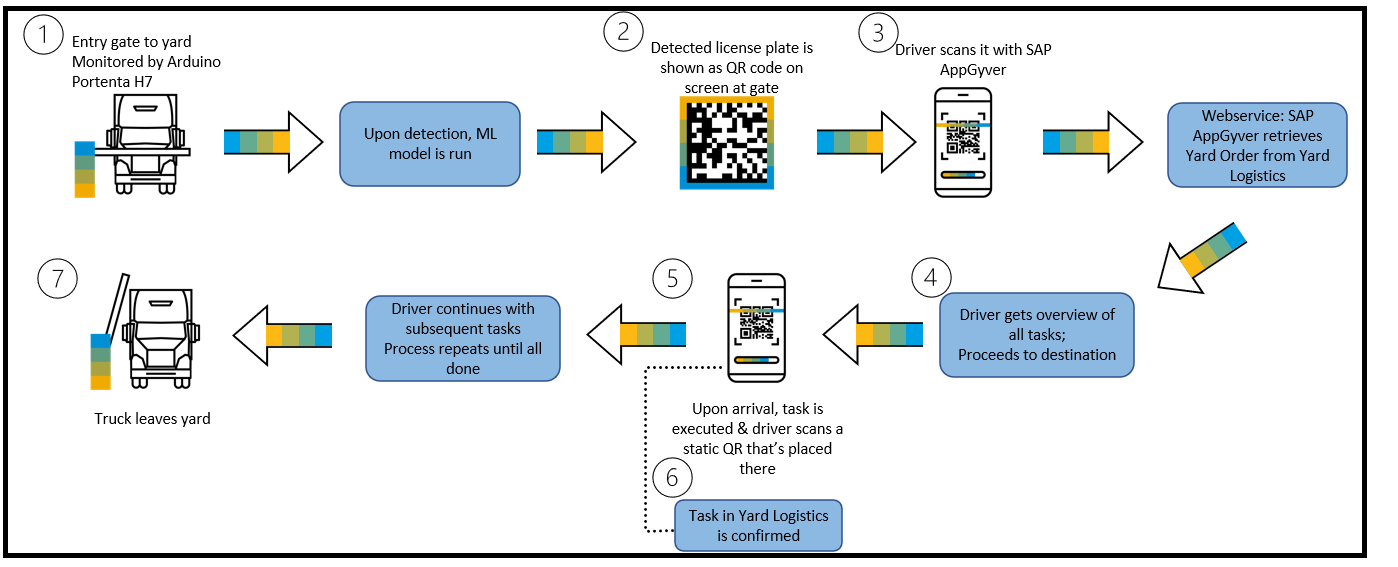

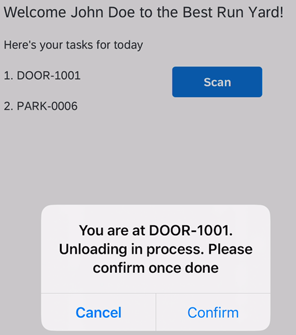

An automatic license plate recognition algorithm was created that can identify each truck uniquely without any action being required by the driver. When a truck first approaches the yard, the plate number is detected, and by checking that number against the data in Yard Logistics, the system determines if the driver should be allowed into the yard. If so, they are given a list of tasks to complete for the day that they can view in a smartphone app. This list specifies each location that they need to visit, and in what order, to complete the loading or unloading of the truck. When they arrive at each station, an automatic license plate recognition algorithm automatically checks them in so that work can begin and that step can be completed. After all tasks have been completed, the driver can leave the yard and continue their work. SAP found that this streamlined check-in process was six times faster than traditional manual processes.

One of the driving factors behind SAP choosing to use the Edge Impulse machine learning development platform was their desire to deploy their solution to microcontrollers. Computing on the edge, as opposed to in the cloud, offers many benefits related to privacy, latency, communications bandwidth, and cost. They found that reductions in latency were especially important to their goal of running real-time inferences. And with the low cost of microcontrollers, it was possible for them to deploy devices to the many locations where machine learning algorithms were needed without burdening a company with excessive costs.

The powerful, yet inexpensive, Arduino Portenta H7 board was selected to power the system. With an Arm Cortex-M7 MCU running at 480 MHz, and a second Cortex-M4 running at 240 MHz, there is plenty of horsepower to run a highly-optimized machine learning model created with Edge Impulse. An onboard Bluetooth Low Energy radio gives the platform the ability to wirelessly transmit relevant inference results. The Portenta H7 is fully supported by Edge Impulse, so it is a snap to get it up and running quickly.

With accuracy and speed being critically important to the success of this project, the team devised some very clever methods to optimize the machine learning model. Recognizing that only certain combinations of letters and numbers can possibly appear on the types of license plates they were interested in, they restricted the model to detecting only valid options. This reduced the search space of the algorithm, which in turn reduced model size, latency, and utilization of computational resources.

Given the success that the engineers had with automatic license plate recognition, they decided to build another model that can detect dangerous goods labels on cargo. Since there are special procedures associated with transporting hazardous materials, automated detection of the presence or absence of these indicators could also serve to streamline yard operations, and also enhance safety practices.

SAP’s demonstration is an excellent example of how machine learning can supplement existing processes and lead to substantial increases in efficiency. A careful reading of their blog post on the subject could trigger some ideas that will get you on your way to saving time and money in your own area of expertise.

Want to see Edge Impulse in action? Schedule a demo today.