The rapid evolution of Edge AI has transformed many industries, including manufacturing, healthcare, consumer electronics and more. In manufacturing and industry, one of the main components in this transformation is the intelligent control of Brushless DC (BLDC) motors. Analog Devices' Trinamic Smart BLDC Motors offer a ready-made solution, integrating advanced motor controls ready for a wide variety of Edge AI projects.

Smart motors differ from traditional motors by incorporating integrated electronic controls and intelligence, with no need for external control mechanisms. These built-in controls allow for self-diagnosis and monitoring, communication with other infrastructure, and fine-grained manipulation of motor speed or movement. ADI’s Trinamic series of smart motors offers these features, as well as optimized energy efficiency, in an off-the-shelf package.

Due to their ability to provide granular data and vary their operational states, Trinamic smart motors are well suited for tasks such as robotic arm assembly tasks, autonomous vacuums, conveyor belt drive systems, assembly line propulsion, advanced surgical equipment, and more. Other common uses are in the construction equipment, fabrication machinery, food production, and smart HVAC systems.

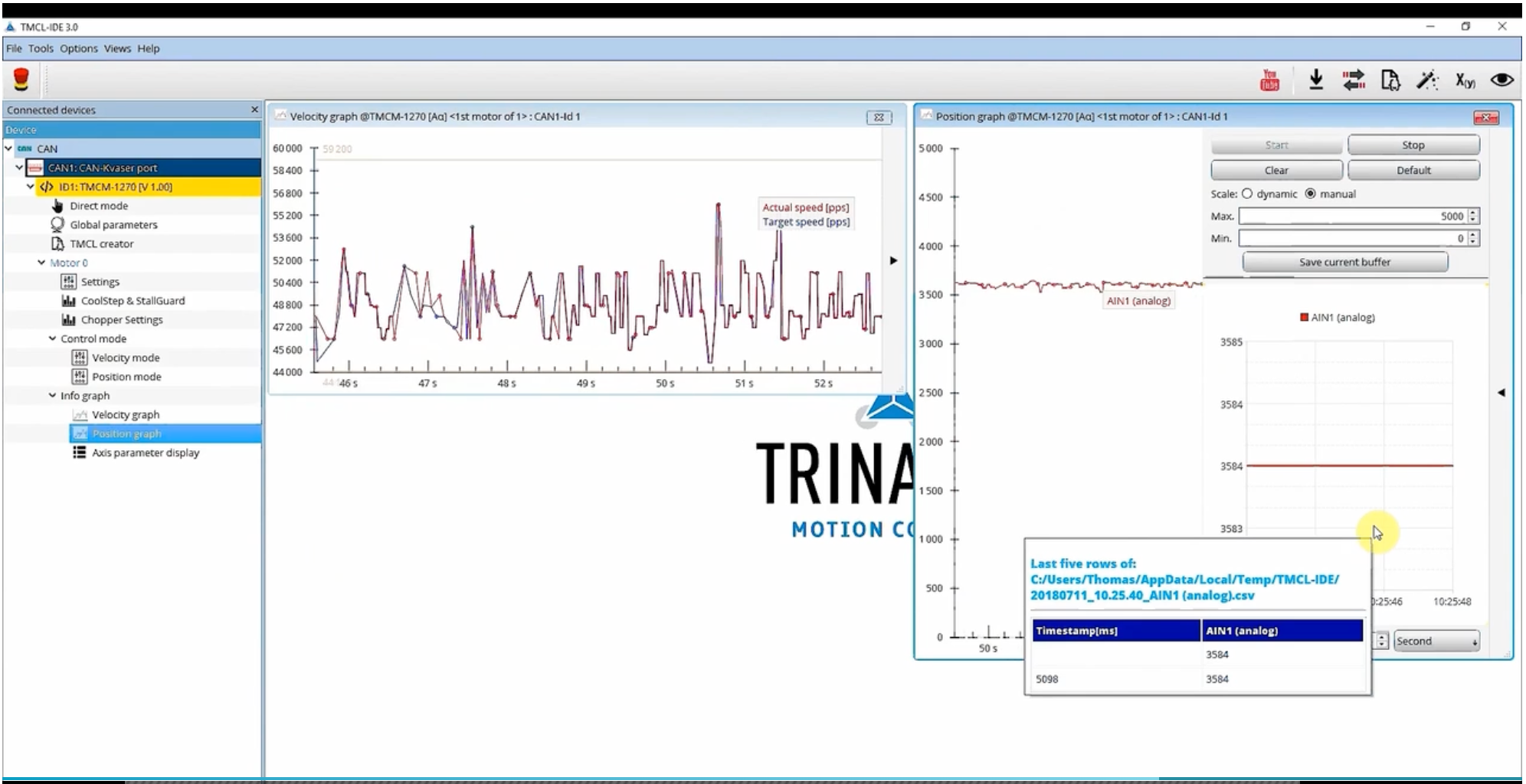

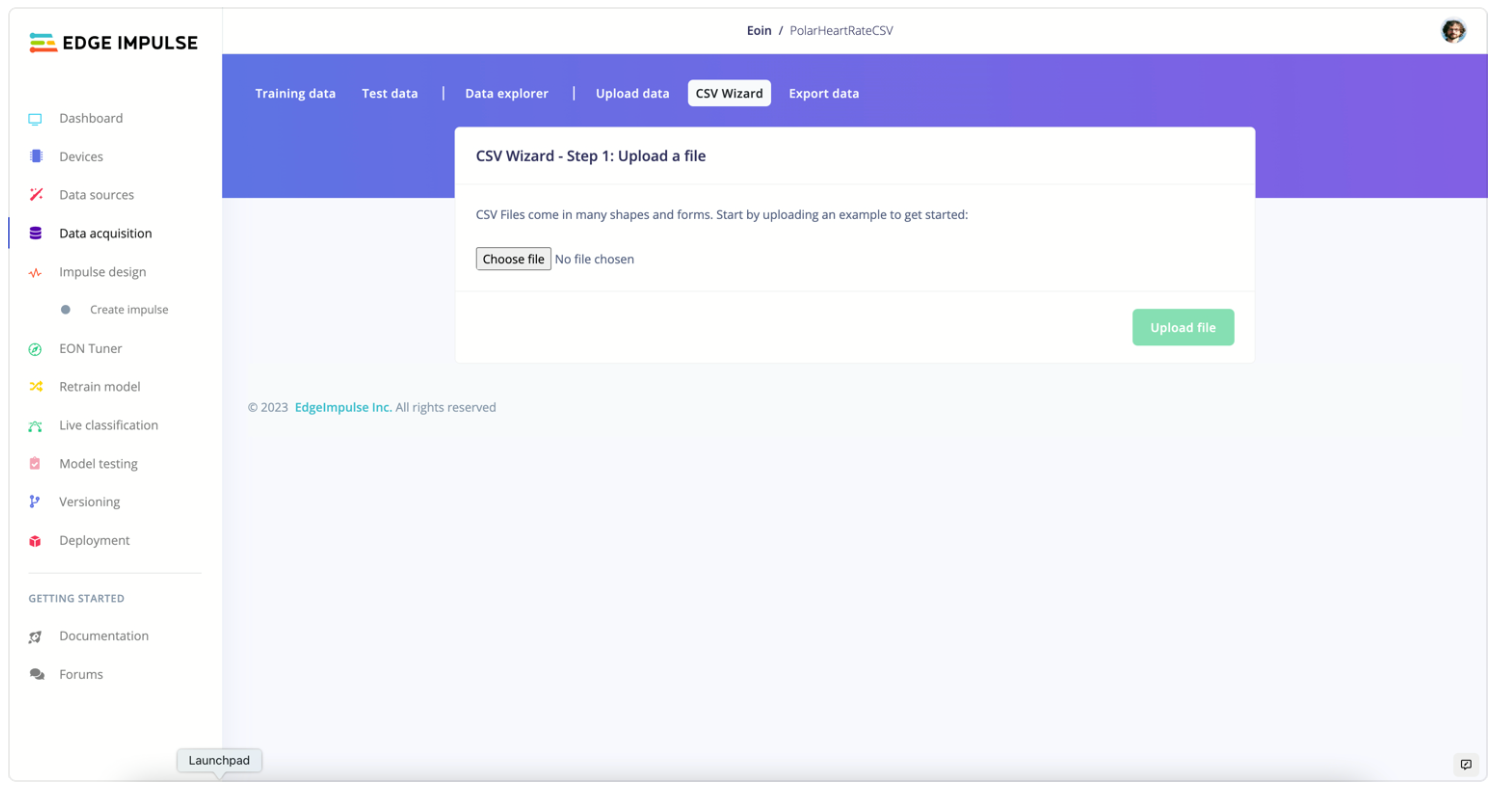

Analog Devices provides a software stack called TMCL-IDE to interface with and capture data output by Trinamic motors, making it easy to upload custom firmware applications as well as visualize sensor output from the motor. The TMCL-IDE application also has the ability to output the data into .csv format, which in turn can be easily imported into Edge Impulse through the CSV Wizard in the Studio.

In the documentation (here using the PD-1670 model as an example), you will also find that:

The firmware of the module can be updated via the serial CAN interface. As an alternative to TMCL, a CANopen firmware is available. The PD-x-1670 contains the following main components:

- Microcontroller (ARM Cortex-M4), responsible for overall control and communication

As a result, you can then proceed through the steps of building you machine learning model through the Edge Impulse Studio, and once you reach the Deployment phase, you can simply export a C++ Library and then integrate the model and it’s supporting files into your TMCL-based application.

Finally, you can return to TMCL-IDE to deploy the firmware project to the smart motor, which will then run inference locally, and be able to detect anomalies or other trained motions or movements.

If you need any assistance getting started with an Analog Devices Trinamic Smart BLDC Motor, be sure to reach out to us!